Nextwaves Industries Transforms Inventory Management with RFID Technology

5/28/2025 – Nextwaves Industries

Nextwaves Industries Transforms Inventory Management with RFID Technology

Nextwaves Industries, Vietnam's leading designer and manufacturer of RFID equipment and components, is revolutionizing inventory management across various sectors with its advanced UHF RFID solution. This technology addresses the significant limitations of traditional inventory methods that still dominate most businesses in Vietnam.

Currently, most businesses in Vietnam manage their warehouses manually, using handwritten notes, Excel spreadsheets, or relying entirely on staff to scan QR codes. As warehouse operations scale up, these methods reveal significant limitations. Inventory checks are time-consuming, prone to errors, and unable to closely monitor stock movements. Losses and inventory discrepancies are often discovered too late, after the damage has been done. Typically, businesses need one to two days to complete a full inventory count, which is only done weekly or monthly.

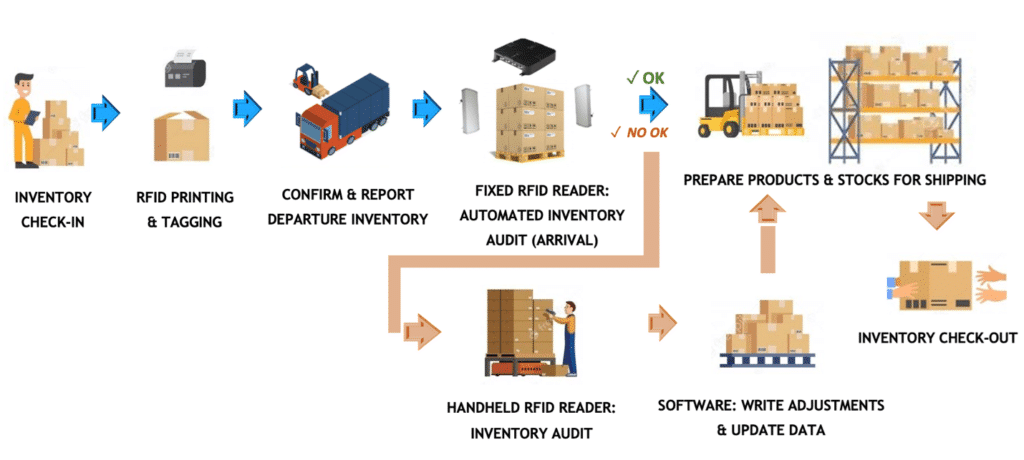

Nextwaves' UHF RFID solution helps businesses eliminate these manual inventory barriers. Each product is tagged with an EPC identifier, allowing staff to scan multiple items at once using handheld or fixed readers, without direct contact or opening boxes. With only two staff members, a 2,500 square meter warehouse can be inventoried in just one to two hours. Data is updated instantly with high accuracy, enabling real-time management and early detection of discrepancies.

This technology dramatically transforms operations by increasing the frequency of stocktaking from every few months to every week or even every day – something nearly impossible with manual processes. Inventory checks become automatic, fast, and do not interrupt operations, allowing instant data updates, early error detection, greater transparency, and more accurate decisions in supply chain management.

Customers who have implemented Nextwaves' RFID systems and customized antennas report an average efficiency increase of 80–90% in their operations. From frontline staff to warehouse teams, manual tasks that once took days are now automated. This automation frees up employee effort, allowing teams to focus on higher-value work.

As the first domestic vertical integrator in Vietnam's RFID sector, Nextwaves Industries designs and manufactures all components in-house, ensuring quality control and customization capabilities. The company's comprehensive approach includes hardware supply, installation, software solutions, and integration support, making implementation straightforward for businesses of all sizes.

With a team of 20 skilled engineers dedicated to designing optimized antennas and wave systems for real-world needs, Nextwaves continues to demonstrate how Made in Vietnam technology can transform business operations and enhance efficiency across multiple sectors.